Services

1-Stop Engineering Solutions in Storage and Intra-logistics Industry

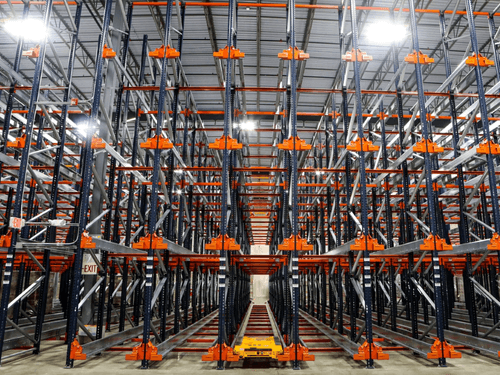

Racking Solutions and implementation

Designing and implementing a warehouse racking solution involves several engineering steps to ensure the system meets the storage requirements,

maximizes space utilization, and maintains safety standards. Here are the key steps:1. Needs Assessment and Site Analysis

2. System Design3. Material Selection

4. Prototyping and Simulation

5. Manufacturing and Fabrication

6. Installation

7. Inspection and Testing

8. Training and Documentation.

9. Maintenance and Upgrades

10. Compliance and Certification

Installation and Inspection

Installing a racking system involves several key steps:

- Site Preparation: Clear and level the area.

- Material Inspection: Check components for damage.

- Marking Layout: Mark the positions for uprights and aisles.

- Upright Installation: Position and anchor uprights.

- Beam Installation: Connect and secure horizontal beams.

- Bracing: Install diagonal and horizontal bracing.

- Safety Features: Add rack protectors, anti-collapse mesh, and load signage.

- Quality Check: Inspect the installation for correctness.

- Load Testing: Verify load capacity.

- Documentation and Training: Provide usage guidelines and train staff.

This ensures a safe and efficient racking system tailored to warehouse needs.

After Sale Service

After-sale service for storage racks includes:

- Regular Inspections: Schedule periodic inspections to check for damage or wear.

- Maintenance: Perform routine maintenance, such as tightening bolts and checking for corrosion.

- Repairs: Provide prompt repair services for damaged components.

- Upgrades: Offer upgrades to accommodate changes in storage needs.

- Training: Provide ongoing training for warehouse staff on safe usage and maintenance.

- Support: Offer customer support for troubleshooting and technical advice.

- Compliance Checks: Ensure racks meet safety and regulatory standards through periodic audits.

These services ensure the longevity, safety, and efficiency of the racking system.

© Since 2008